Delivery Technologies for Diversified Products

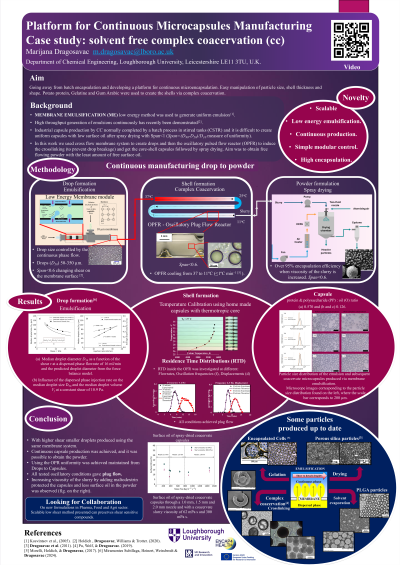

(149) Manufacturing near monodispersed solvent free complex coacervation microcapsules at industrial scale

Introduction: Encapsulation of bioactive compounds is essential in industries like food, pharma, and cosmetics. Complex coacervation [1], a phase separation-based technique, enables the formation of polymeric microcapsules for controlled release. However, achieving monodispersity remains challenging. This study presents an optimized method for manufacturing nearly monodispersed complex coacervate microcapsules, improving uniformity, encapsulation efficiency, and stability, with broad applications in targeted delivery systems using scalable cross flow membrane system [2].

Learning Objectives:

- Understand advantages of the membrane emulsification over conventional emulsification.

- Create oil filled capsules via complex coacervation with variable shell thickness and size.

- Develop drying step to minimise the moisture content following emulsification and coacervation.

Sandra Heinert – Researcher, Symrise; Daniel Miramontes Subillaga – PhD Candidate, Loughborough University; Jenny Weissbrodt – Head of Research, Symrise

Marijana Dragosavac, PhD (she/her/hers)

Reader in Particle Engineering

Loughborough University

Loughborough, England, United Kingdom